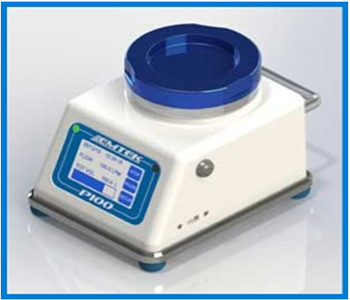

Air monitoring equipment

Desired Equipment

Certain equipment characteristics make some air monitoring devices unsuitable for cleanroom or laboratory environments. Problems such as material discharge, sample volume loss at test locations, unfiltered exhaust, and airflow disruption can arise when using an inappropriate air sampling device. Additionally, bulky or large devices are difficult to install or position for testing purposes.

An Ideal Design

A good air sampling design will overcome the major design issues of smaller devices. Look for a HEPA-filtered exhaust system that discharges particles away from critical areas, a device that is easy to disinfect or clean, and a device that is compact, low-profile, and easy to install. Additionally, it should have: Remote operating controls that make it easy to manage the sampling process remotely, outside, or away from the critical environment being tested.

Some Considerations

When considering a new air sampling device, you should consider the following factors: The type and size of the bacterial particles to be sampled, the sensitivity of those microorganisms to the test parameters, the concentration of those bacterial particles, and the ability to detect high or low levels of bacterial contamination. Additionally, consider: The appropriate culture medium to detect the desired bacteria to be collected, the time and duration of sampling.

The wrong air sampler can affect everything you do. However, choosing the right air sampler will help you monitor important environments, ensure the device does not negatively impact the environment, and ensure the samples and data collected are accurate.