Understanding air monitoring devices

Environmental Contaminants

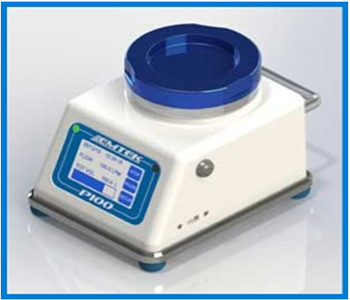

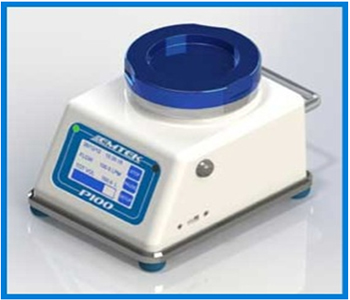

Different environments are susceptible to different types of contamination and have different monitoring requirements. In Pharmaceutical, Biotechnology and Hospital environments, the air in cleanroom environments must be tested for both non-living particles (e.g., Dust, dander, aerosols, pollen, etc.) as well as living particles (e.g., bacteria and molds).Different equipment is required to test for these two different pollutants, including unique sampling equipment for collection and detection. It is important to determine your specific needs before beginning your air sampling plan.V100 Controllerour R2S , RAS or RCG sampling heads and our P100 air sampler, for example, is designed to collect bacterial particles.

Volume and speed

Each environment requires its own testing standards. In some cases, a small, quick sample is sufficient to assess air quality. In other cases, you may need a longer collection time with a larger total volume, allowing you to collect more particles and draw more conclusions about the working environment around the sampler.Different samplers offer different potential total collection volumes (10 cubic feet, cubic meters, etc.) and sample collection rates (e.g., 28.3, 50, or 100 LPM) – always compare these sampling parameters with your sampling requirements.

Interface

Like any other high-tech device, the data collected from an air sampler will be most accurate when the operator is properly trained.Spending the extra time or money to purchase a sampler with an easy-to-use interface often pays off in the long run, as it reduces the learning curve for new employees and provides accurate results. User error is a consideration in any field, but user error (e.g., false positives and/or false negatives) when sampling air can have serious consequences (e.g., impacting shipments, causing product loss, etc.).